From creating quotes to managing component obsolescence and end of life, ES discovers how Nemco’s purchasing team plays a vital role, adding value through effective supply chain managemen

From creating quotes to managing component obsolescence and end of life, ES discovers how Nemco’s purchasing team plays a vital role, adding value through effective supply chain managemen

How does Nemco’s purchasing team assist new clients?

As soon as we receive an enquiry, a dialogue is opened between the customer and the quotes team where we will discuss their requirements. We will set about putting that quote together and any queries or issues that arise during this process are fed back to the customer so a resolution can be reached together in line with the customer’s aims.

The purchasing team strive to provide the full kit of materials in a timely fashion. Where the first customer order is a prototype, every effort will be made to avoid high minimum order quantities and material redundancy, seeking samples direct from manufacturers where possible.

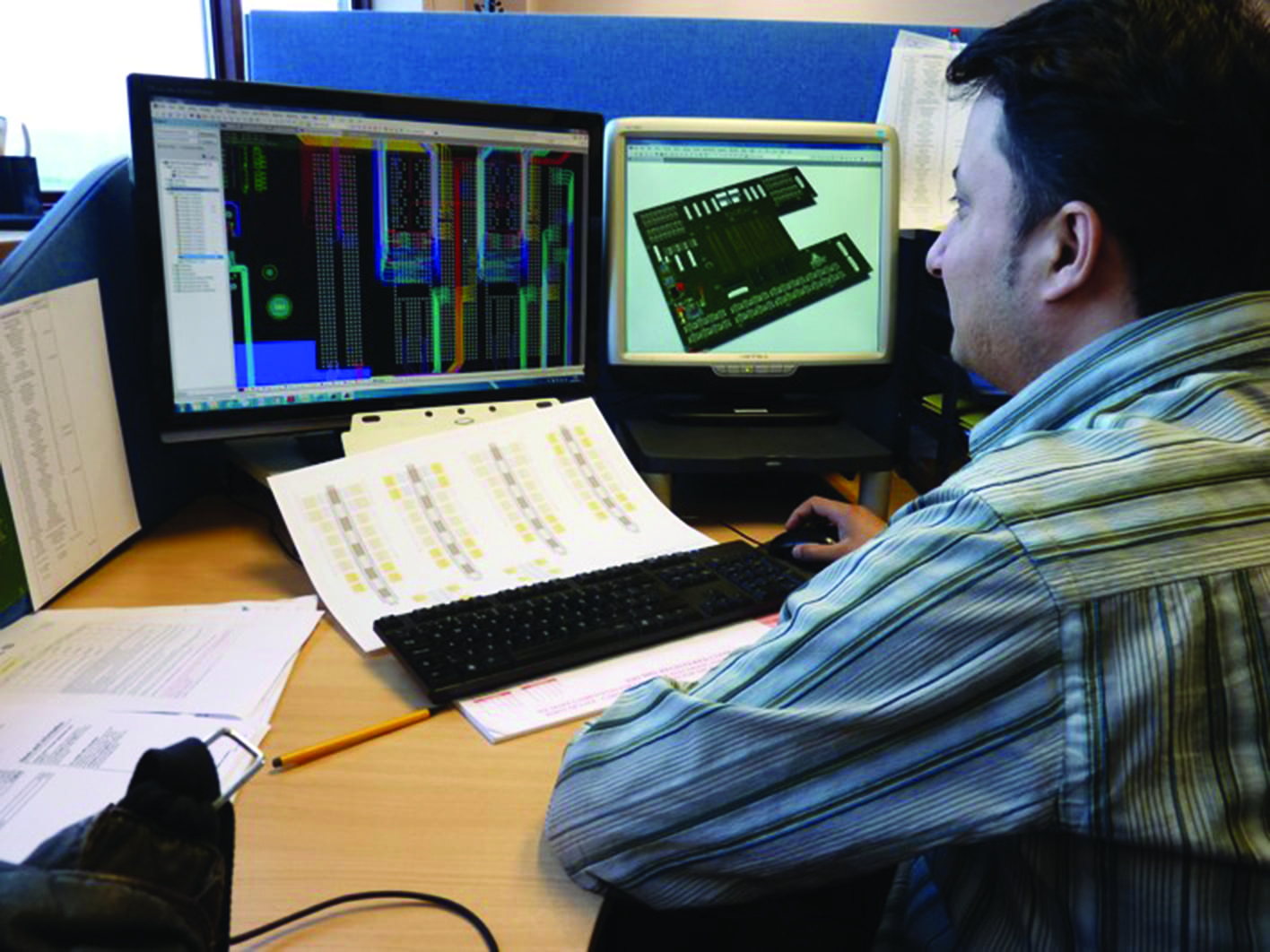

Does the purchasing team work with the design engineering team and what input does the buying team have on component selection?

Purchasing work with engineering as early as possible to provide data and obtain samples if needed.

When EOL or obsolescence situations arise, what happens and how are clients notified?

Product change notices and end of life notifications from suppliers are collected and communicated throughout the business via a controlled process. The engineering and sales teams are notified upon receipt of end of life, enabling either team to inform the customer of their options. Purchasing may provide samples, data or a one-off last time buy. If obsolescence is captured during the quote stage, the customer will be notified before quote submission and provided with any suggested alternatives and as much information from the manufacturer as possible. Between the customer and Nemco a solution is then agreed upon which is reflected in the quote.

How are new client quotes calculated?

We consider not only the number of components placed but also the type of components being placed and if it is going to be placed by hand or machine. Any other customer requirements such as test or coating processes will also be included in

the quote.

Is Nemco experiencing extended lead times and what effect does this have on production?

Extended lead-times are much improved, with just a few lines still problematic. There is some suggestion from some of our preferred suppliers that multilayer ceramic capacitors could extend again, but so far, there is no evidence of this.

Over the last 24 months has Nemco increased or decreased its preferred supplier list?

Our list has remained static. Although reducing the vendor base would be ideal, our customer base and range of products does not easily lend itself to vendor reduction.

How has the purchasing team’s role changed over the last five years?

Some roles at Nemco have changed in the last few years. For instance, customer costings have been split from purchasing and moved to sales to increase focus on the separate tasks involved. There has also been a tightening up of risk mitigation and supplier evaluation.

Overall, how are principal component manufacturers and distributors supporting the Nemco buying team?

Nemco encourages supplier partnerships and actively seeks out suppliers that offer good service and supply across all products along with advantageous terms.