TCL Elektronika explains its design for manufacture process and how it selects manufacturing locations based on the required technology, quantity and price point

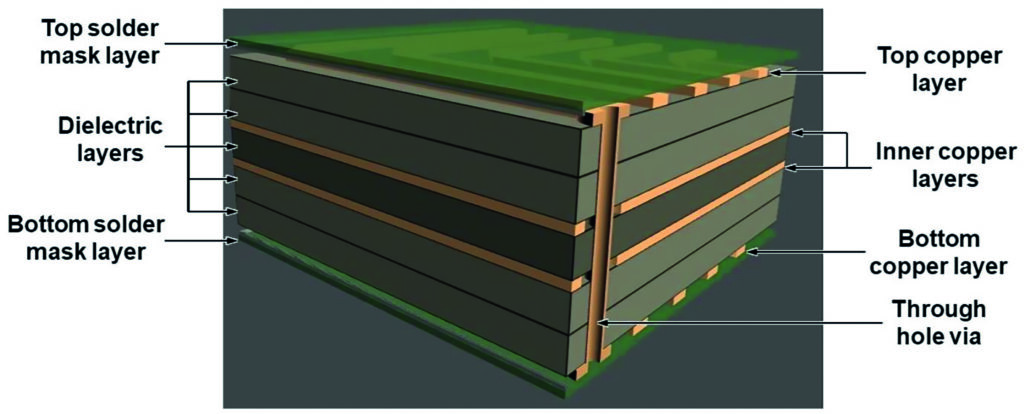

Printed circuit boards come in a variety of forms and technologies, including multi-layer, heavy copper, rigid-flex and ceramic. To ensure electronic devices perform efficiently and reliably, purchasers should choose PCBs designed and manufactured to the highest standards.

The first step is the design process. Adherence to industry standards, such as IPC, is crucial. IPC publishes the most widely used industry standards in the manufacturing of printed circuit boards.

It is also important to select appropriate materials and surface finish. Factors such as heat tolerance, heat management and wire bonding requirements must be considered. TCL Elektronika supports PCB designers, providing guidance on materials and manufacturing processes, plus conducting full manufacturing feasibility studies when necessary.

Once the design for manufacture process is complete, TCL Elektronika determines the best production source for the required technology, quantity and price point. For urgent requirements, such as heavy copper PCBs, the company uses its own European manufacturing specialists. For other technologies, TCL Elektronika may place the requirement with one of its Asia manufacturing partners, which are audited by the company’s Group personnel in Hong Kong and China. While Asia manufacturing offers the lowest cost, TCL Elektronika carefully selects the appropriate factory to best fit the PCB design and production requirements.

www.tclelektronika.com