Join Cupio Services at ECS to explore the benefits of deploying x-ray, acoustic, optical and electronic test, inspection and analysis services

Join Cupio Services at ECS to explore the benefits of deploying x-ray, acoustic, optical and electronic test, inspection and analysis services

Cupio Services’ Basingstoke-based 3,000ft² facility services clients across the UK and Europe. No manufacturing process can be 100 per cent guaranteed so there is always a need for inspection and test and, in the event of a final product issue, failure analysis. Cupio’s skill lies in identifying which equipment best fits the task based on material, projected fault type, invasiveness and level of detail required. Once the equipment is agreed, Cupio goes to work identifying areas of non-compliance and reporting findings.

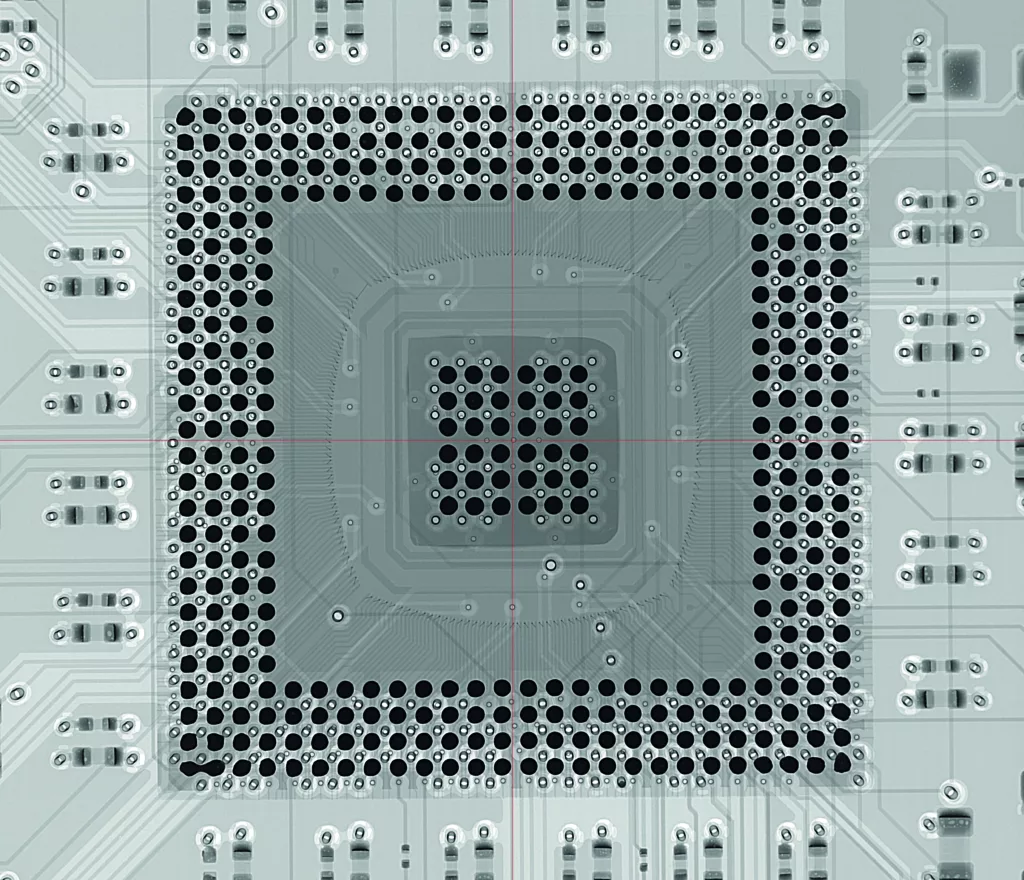

The company’s analytical equipment has four core areas. SAM is a non-invasive and non-destructive technique used to inspect for defects in solid samples, components and materials or structures. X-ray is the best known technique for failure analysis due to its non-destructive ability to image the interior of products to identify hidden defects. AOI is an automated visual inspection where a camera is used to autonomously scan the device or board. Finally, electrical test looks for faults in boards and devices which can’t be seen.

Cupio Services both sells systems (with product lifetime support) and provides a contract inspection and analysis service at its Basingstoke facility. It all comes down to three key elements: cost, time and reputation.

It can cost millions if products are recalled or returned. The further down the manufacturing process a fault gets, the higher the cost. A recall being the costliest of all. The sooner the fault is identified the lower the cost.