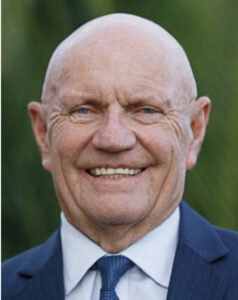

Lansdale Semiconductor’s president, R Dale Lillard and Electronic Components’ president, Rich Nadeau, highlight how 10-years of effort has reduced counterfeiting problems.

Counterfeits began to increase in the 1990s and 2000s, primarily through purchases from brokers and distributors sourcing components on the internet. The largest market was long-life applications where the system outlived the component’s life cycle. The aerospace and defense industries have the longest system lives and were targeted by counterfeiters when component supplies dried up.

Counterfeiters also filled the void for popular parts when lead times were long or supply was scarce. Purchase awards were often given per the DFAR to the lowest bidders regardless of the supplier’s trustworthiness.

In 2007, industry and government recognized counterfeit problems were growing and formed a representative team initiated by the Aerospace Industry Association. It included industry associations, contractors and government agencies and was set up to establish recommendations to mitigate counterfeits. It formed an Integrated Project Team and reported its recommendations in 2011. Among the recommendations were:

1: Implement specification SAE AS5553 in organizations.

2: Establish a Government audited Qualified Supplier List of Distributors and Qualified Test Supplier List who follow SAE AS6081 specifications. These distributors and brokers will be trusted suppliers. The Defense Logistics Agency established a new system to audit, qualify and monitor brokers and distributors. This reduced the suppliers capable of selling to the DLA significantly. It required a DLA audit to JEDEC specifications AS9120 and testing requirements AS6081 and AS6171. DLA purchases were focused on QSLD suppliers.

As a result, when the National Defense Authorization Act of 2012 Section 818 (which worked to minimize purchases of counterfeit components) was passed, purchasing electronic components for defense and aerospace contracts changed dramatically. The law significantly tightened the procurement rules for components, passing financial responsibility back to the contractors for any costs to mitigate and rework problems associated with counterfeits. In the event a contractor or supplier intentionally purchases counterfeits for government contracts, the individual or company can be fined up to $15,000,000 and imprisoned for up to 20-years. With the NDAA 2012-818 passed by Congress, purchasing guidelines established by industry and government to mitigate counterfeits became mandatory, not suggestions.

The NDAA revised the Department of Defense Federal Acquisition Regulation to address detection and avoidance of counterfeit electronic parts. It required government departments and department contractors and subcontractors to have a counterfeit mitigation plan. It required them to purchase components primarily from the original manufacturers or their authorized dealers and obtain electronic parts not in production or not currently in stock from trusted suppliers. It established a procedure for qualification of trusted suppliers to be audited by department officials. It also utilized the Government Industry Data Exchange Program to communicate about suspect counterfeit components in the supply chain.

Industry and Government procurements of electronic components are now more focused to prevent counterfeits entering the supply chain. They are more concerned about purchasing from original manufacturers and their sales channel, authorized aftermarket manufacturers and their sales channels and trusted QSDL distributors to minimize counterfeits. This has led to a reduction in the problems caused by counterfeits in the supply chain and greater reliability for the systems that use them.