Rochester Electronics introduces buyers to an array of services specifically designed to mitigate the semiconductor shortages the industry is currently experiencing

Current semicond uctor shortages are widespread. Few manufacturers and product families have been spared extended lead-times and even allocation. Though the automotive market leads the charge to secure supplies in a lean supply chain, all other market sectors are affected, or may soon be affected. Customers are under pressure to guarantee supply, with grey market or unauthorized sources often seen as the only solution. This could not be further from the truth. Rochester Electronics, an authorized after-market supplier, offers risk-free sourcing and alternative solutions to keep lines running.

uctor shortages are widespread. Few manufacturers and product families have been spared extended lead-times and even allocation. Though the automotive market leads the charge to secure supplies in a lean supply chain, all other market sectors are affected, or may soon be affected. Customers are under pressure to guarantee supply, with grey market or unauthorized sources often seen as the only solution. This could not be further from the truth. Rochester Electronics, an authorized after-market supplier, offers risk-free sourcing and alternative solutions to keep lines running.

Top semiconductor manufacturers have partnered with and authorized Rochester Electronics to manage their surplus active stocks during times of plenty. In some instances, Rochester has taken control of all material after last-time-ship. As the market moves from surplus to deficit, Rochester’s authorized stock is an essential buffer to help customers avoid line-stops. Rochester Electronics can provide instant stock of active parts which are typically older date-code but backed by the original manufacturers and stored to AS6496 standards. Product is supplied with full warranties and guarantees.

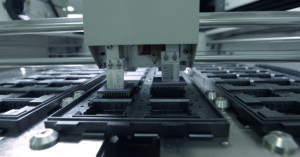

As a 100 per cent authorized source of supply, anti-counterfeiting standards that apply to independent suppliers such as AS6171 and AS6081, are not required. Alternative solutions include discontinued stock from other historically approved suppliers, different temperature/speed grades, different packages and older die iterations or build versions (eg plating standards, gold instead of copper bond-wire, etc). Reverting to a previous design or making minor design modifications (which do not trigger a full system re-qualification) can often be an alternative to a line-stop. Rochester is also licensed to continue building many. end-of-life semiconductor product families. Products are built using original known-good-die, tested using original test processes and marked with the original part number. Where Customers struggle to build current products, some are re-starting the production of older designs or extending the service-lives of product in the field, to fulfil market demands.

www.rocelec.com