You’ll need sensors to complete your new appliance, building automation product, or automated manufacturing system. You may need customization for a specific sensor assembly. While price and delivery are critical decision factors, other considerations determine a successful sensor selection.

Here are some essential facts about your sensor choices and four crucial questions whose answers should carry significant weight in your decision process.

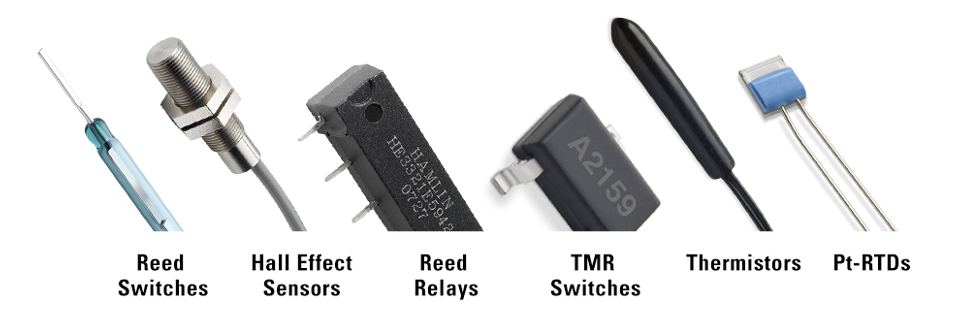

Magnetic detection sensors for proximity detection, positioning, and control

Reed switches have two ferromagnetic blades (reeds) hermetically sealed in a tubular glass envelope. The contacts on each reed have a thin layer of precious metal to provide a low resistance electrical connection. The glass envelope is filled with nitrogen gas to eliminate oxygen and prevent contact oxidation. Reed switches activate by either a permanent magnet or an electromagnet. The relative stiffness of the reed blades, the small gap, and the overlap between the two contacts determine the switch’s sensitivity, defined by the intensity of the magnetic field required to change the state of the contacts. Unlike an integrated circuit sensor, a reed switch does not require power to operate. Thus, a reed switch is an excellent control element in battery-powered products.

Hall Effect sensors generate a voltage when exposed to a magnetic field intensity and when supplied by a source current. The sensor is a semiconductor-based material. Hall voltages are microvolt and millivolt levels; thus, a Hall effect sensor requires signal conditioning. In addition, the semiconductor element requires temperature compensation and EMC/ESD protection. Hall effect sensors monitor proximity and provide continuous rotary or linear positioning.

Reed relays combine a reed switch and control coil. As with other relays, this provides galvanic isolation between the coil control circuit and the controlled load. The reed relay’s small size and high magnetic efficiency enable lower coil drive power than other relay types. Other advantages include high insulation resistance, low contact resistance, and long contact life.

TMR switches integrate Tunneling Magneto Resistance (TMR) and CMOS technology to provide a magnetically triggered digital switch with high sensitivity and ultra-low power consumption. It contains TMR magnetic sensor and CMOS signal processing circuitry within the same package, including an on-chip TMR voltage generator for precise magnetic sensing, a TMR voltage amplifier, and comparator plus a Schmitt trigger to provide switching hysteresis for noise rejection. An internal bandgap regulator provides a temperature compensated supply voltage for internal circuits, permitting a wide range of supply voltages.

Temperature sensors

Thermistors are thermally sensitive resistors whose resistance is a function of their temperature. Negative temperature coefficient (NTC) thermistors decrease their resistance when the temperature rises, and Positive Temperature Coefficient (PTC) thermistors increase their resistance when the temperature rises. Thermistors provide high accuracy over a narrow range of approximately -50 °C to 100 °C. Thermistors have highly predictable characteristics and excellent long-term stability; they’re ideal sensors for temperature measurement and control applications.

Platinum Resistance Temperature Detectors (Pt-RTDs) have a near-linear change in resistance with any temperature changes. Platinum RTDs maintain a significant and uniform rate of resistance change over a much wider operating temperature range than a thermistor. Platinum RTDs are excellent for measurement and control applications with temperatures ranging from -70 °C to 500 °C.

4 Questions to Ask Before Selecting Sensors

1. Does the supplier offer a wide-ranging sensors product line and other components?

Consider a manufacturer that produces multiple sensor types. Such a manufacturer has expertise in a broad range of technologies and is more likely to have capabilities to meet custom requirements.

In addition, a manufacturer with an extensive product line can address many of your other component requirements. That allows you to reduce the number of vendors and simplify your supply chain.

The manufacturer’s knowledge and experience with an extensive portfolio can translate into innovations in new products. Their innovations can give your products a decisive competitive advantage in the market.

2. Does the supplier offer application assistance?

Application assistance from technical personnel can save precious development time and help select the appropriate sensor model. They can ensure that you consider all parameters related to the use of the sensor, such as temperature effects, vibration, and susceptibility to electrical noise.

3. Does the supplier provide custom engineering?

Do you have critical size or shape requirements for your sensor? Maybe you need slightly more sensitivity or a specific type of electrical connector. You will want your supplier to have custom engineering capability to address unique needs. Many suppliers sell only their standard products, and that lack of service should preclude any expectation of having a long-term relationship with the supplier.

4. Does the supplier have the capacity to manage your order requirements?

You do not want to lose revenue due to unduly long lead times for sensors and other components. Ensure that your supplier can meet your forecasted order requirements and adequately respond to unexpected large orders.

Benefits of selecting a capable sensors supplier

While a supplier can meet the essential requirements discussed here, the price for their sensor may not be the lowest available. However, you benefit from savings in development time, reduced in-warranty expenses, higher reliability, and greater customer satisfaction in the long term. Supplier selection should be as important as the selection of your sensors.

Additional questions to ask about sensors

Download the white paper, Eight Considerations When Purchasing Sensors, to learn about other questions you should consider before selecting your sensors and the company that manufactures them. Also, see the Sensing Products Selection Guide for more information on choosing the best sensors for your application, courtesy of Littelfuse, Inc.