Pektron explains how the process of sourcing contract design and manufacturing services is influenced by the nature of a project.

Pektron explains how the process of sourcing contract design and manufacturing services is influenced by the nature of a project.

OEMs deciding to outsource their electronics manufacturing do so for many reasons and those reasons will directly influence the CEM they select.

Scenario 1: What if the OEM is looking for a straightforward build-to-print? Let’s say they have a design and simply want it manufactured. In this case they will be looking at SMT manufacturing facilities and volumes. Does the CEM have the capability and capacity to deliver what is needed?

A word of warning though. Even the most apparently simple build-to-print projects can present issues around design or manufacture, so keep an open mind. Is the CEM expected to be proactive and highlight issues, offering opportunities to improve design and manufacture leading to reduced costs/timescales and improved quality/reliability? If so, this should be factored in.

Scenario 2: What if the OEM has a technical challenge, physical limitation or perhaps no design at all?

Some OEMs will outsource the entire design, letting the CEM write the initial specification. Others will have a specification which the CEM will work with. Either way, the OEM’s engineers and designers will be working closely with the CEM to discuss what needs to be achieved, agreeing roles/responsibilities and working closely as the design and development progresses. The OEM might also want to explore the CEM’s experience in technical innovation, market sector expertise, production engineering capability, accreditations, enclosures, testing and validation facilities.

Scenario 3: What if the OEM needs to reduce costs and timescales? Outsourcing design and development can reduce costs and timings.

Likewise, the OEM should explore the CEM’s experience in managing their supply chain and working with suppliers to source components at competitive prices and within timescales.

Often, CEMs can reduce time-to-market via component lifecycle and availability analysis, which may lead to increased yields, reliability and cost efficiencies. Question how the CEM is coping in the current environment? How successful is it sourcing parts, finding alternatives and using the grey market?

Depending on the scenario weigh up the relative importance of a CEM’s key attributes including:

• Quality standards and industry accreditations

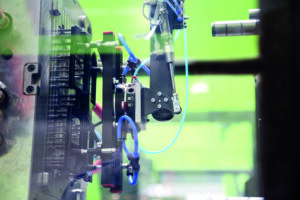

• Facilities: SMT lines, assembly capabilities

• Technical support

• Design and development

• Testing and validation facilities

• Quantities/volume capabilities

• Flexibility and responsiveness

• Supply chain: Traceability and obsolescence management

• Account management, personal relationships and named contacts

• Areas of experience and expertise

While an online search will provide some information, it’s more than a tick box exercise. It will always require a phone call or visit involving the OEM’s design or engineering colleagues speaking with the CEM’s counterparts.

Working with a CEM is a long-term commitment, based on respect, trust and clear communication. People buy from people and strong relationships build success so meeting the people and understanding the business is important.

In addition, a CEM may be able to add value in atypical areas such as: investment (CEMs keep pace with the latest equipment); testing and validation (onsite facilities reduce timescales and costs); and injection moulding (developing the enclosure alongside the electronics can deliver time and cost benefits).