levadata.com/semiconductor-lead-time-updates-the-forecast-for-2022

Flip Electronics’ president, Bill Bradford, offers practical advice for the times purchasing professionals find it necessary to turn to new sources of supply

The past few years have been unprecedented, plagued by a perfect storm of global pandemic, political turmoil, environmental shifts and semiconductor supply chain disruptions. Purchasing professionals must be more strategic than ever to get their jobs done.

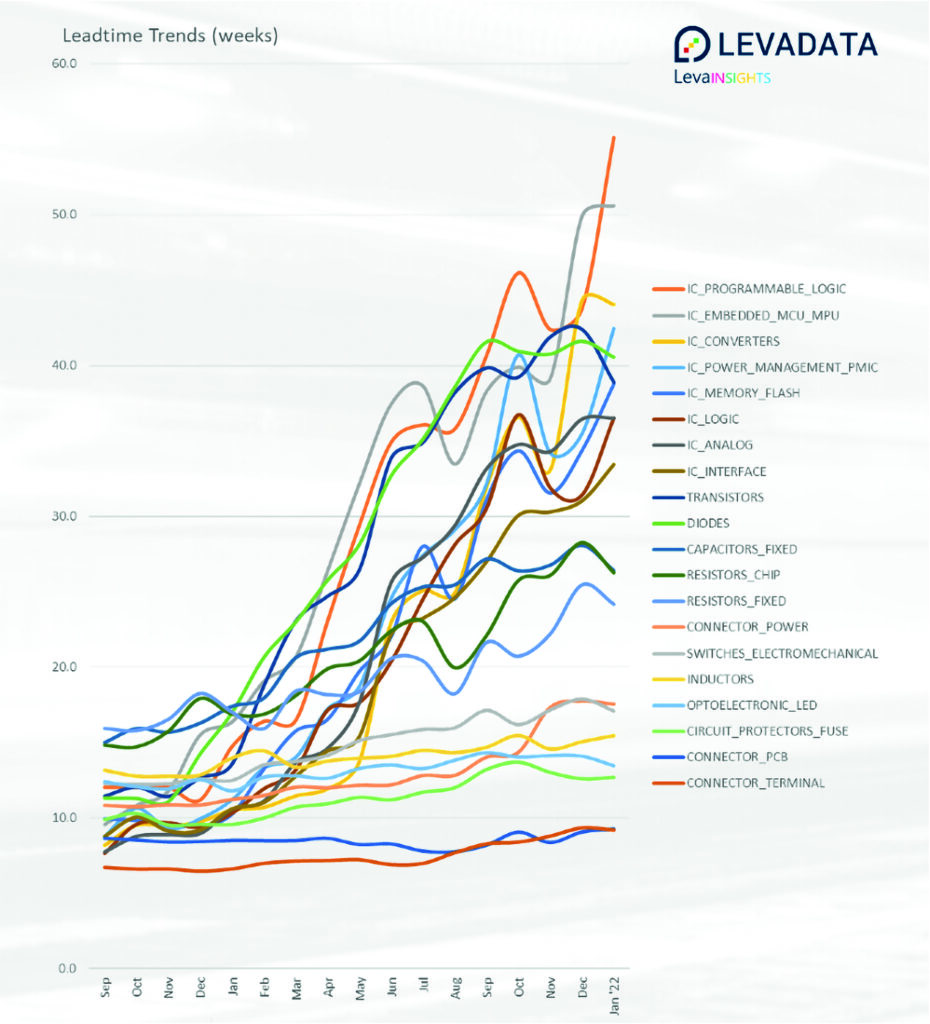

Lead times, fed by capacity, materials and logistics constraints, have stretched to months—a trend likely to continue for at least a couple more years. These constraints extend across most component types.

For many buyers, the challenge to fill critical requirements means bringing on new sources of supply, including specialty and independent distributors, or brokers. Buyers will have to think differently about working with these new partners safely and effectively. Then, if purchasing from the open market becomes unavoidable, organizations will need to focus on counterfeit avoidance.

Before turning to the open market, procurement’s first line of defense should include a strong relationship with a reputable authorized specialist distributor who focuses on hard-to-find products. These partners will communicate clearly about parts they have and how many, plus pricing and delivery. These strategies help purchasers avoid counterfeits.

Disreputable sources will push buyers to make quick decisions and wire funds without providing product specifics, such as date or lot codes, that verify what is being purchased. If a deal seems too good to be true, it probably is. Consider leveraging existing distribution partners to verify new sources. If nobody has heard of them, there’s a real risk they are not legitimate.

Sometimes it’s necessary to turn to new partners. When buying in the open market, good practices around parts verification should become top priority. Define what a counterfeit part is and take steps to identify and eliminate them.

Bad actors are getting more sophisticated. For example, counterfeiters may put a dozen or more genuine parts on a reel, followed by counterfeit parts, hoping the real parts will be tested and the counterfeits will be passed into manufacturing. Others try slipping through working parts that fail to meet specifications.

As counterfeiters get more sophisticated, buyers must become savvier. If forced to the open market for parts, multiple testing levels should be employed, particularly for applications where a parts failure could be devastating.

In this challenging market, the adage of ‘trust but verify’ holds true. Find trusted partners and work closely with them to verify that only genuine product is put into the manufacturing stream.

www.flipelectronics.com