When designing and manufacturing innovative products for the growing renewable energy sector, Jaltek emphasises the importance of partnering with a CEM who shares the vision

Over the past decade, renewable energy production has grown exponentially and is a topical issue worldwide. With rising pollution levels and the ‘energy crunch’, governments are being called to account. As well as addressing global warming, renewable power can help free economies from uncertain fossil fuel prices, reduce energy costs and strengthen market resilience in a time of constant change.

Demand for energy transition means the renewable energy sector is booming. New projects and trends are rapidly emerging, including energy-efficient integrations, digitisation and solutions that overcome the intermittent nature of renewable energy production.

As with traditional energy projects, the manufacture and operation of renewable energy products can be disrupted by supply chain issues, rising material costs, labour shortages and increased shipping costs. The unique features of renewable energy projects can make them more susceptible to supply chain issues. However, there are things stakeholders can do to help mitigate certain risks.

The renewable energy boom has created rising demand for components. One way stakeholders can future proof against supply chain risk is by working with a contract electronic manufacturer that uses bill-of-material management software. This helps identify potential component supply issues by managing BoM health, lifecycle, alternative components, counterfeits and conflict minerals. Coupled with thorough local/offshore purchasing strategies through preferred suppliers, this ensures a supply chain that delivers true added value. Products have a faster time-to-market, lower cost and higher reliability and longevity, all key factors in the renewable energy market.

Whilst technologies used in renewable energy projects are now well understood, the sector is not fully established and remains in the development stage. New technologies are being brought to market and when these technologies are used in practice problems can cause delays.

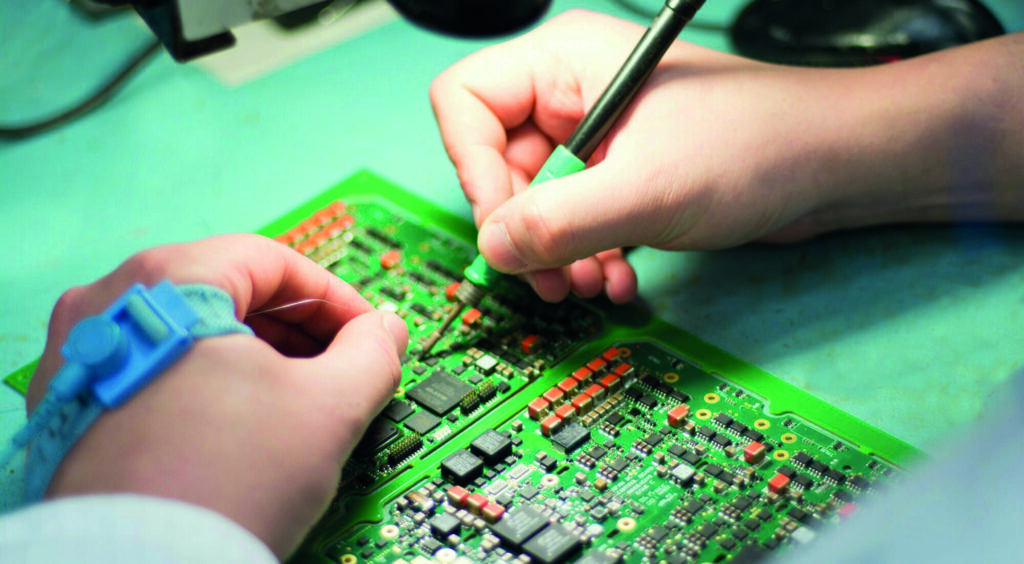

Finding a CEM that offers advanced, innovative and cost effective engineering solutions to support product from concept, through design and development, to commercial success is key. A seamless transition through the prototyping and pre-production stages, to manufacture can then be achieved. This, alongside stringent procurement standards and rigorous inspection and testing protocol ensures products meet the demands of the energy industry.

As concern for climate change grows and demand for cleaner and cheaper energy sources gains momentum, renewable energy growth is poised to accelerate in 2023 with exciting and innovative developments forecast. Choose the right design and manufacturing partner who shares this vision and they will work as an extension of your own business.