Join representatives from CT Production to discover how the company’s investment in people, equipment and processes underpins its 98.41 per cent delivery on time score

Searching for a product manufacturer can be a minefield of options. There are many variables to consider such as price, lead-time, capability, etc, each being more or less important depending on specific requirements. It is important to obtain the correct balance to ensure an OEM’s business needs are looked after and they get what they want, when they want it.

Most manufacturers have similar equipment and facilities, so how does an OEM find the perfect fit? In CT Production’s opinion it is the small things that make the difference. The company prides itself on its levels of customer care and interaction. It also does its utmost to ensure product built quality standards are reliable and end products are delivered on time. If a situation impacts this, the company will always let the customer know at the earliest opportunity and work with them to get things back on track.

CT Production’s primary focus is on its customers and their needs, understanding the importance of customers getting what they are expecting, when they need it. This year’s 98.41 per cent delivery on time and 99.36 per cent yield were both slightly up on last year.

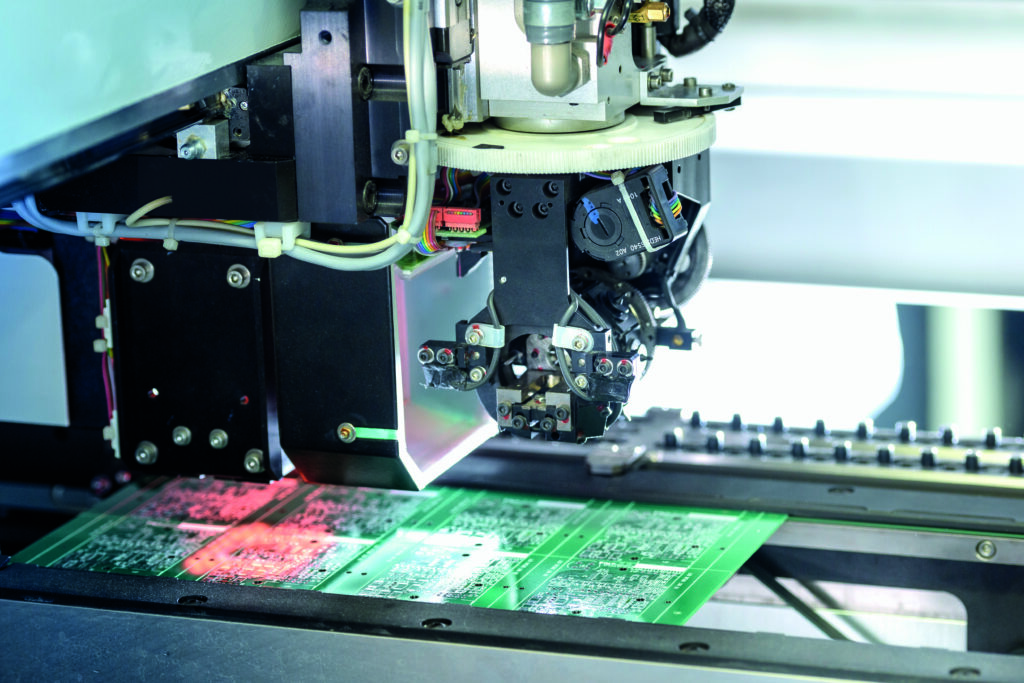

The company is continuously investing in equipment and staff training, with processes controlled to AS9100 (ISO9001:2015) and workmanship to IPC610.

Services range from surface mount to turnkey assemblies for every sector, from prototype to volume.