When choosing a cable assembly partner, GTK suggests picking a company which offers a holistic approach to product quality and cost reduction.

When choosing a cable assembly partner, GTK suggests picking a company which offers a holistic approach to product quality and cost reduction.

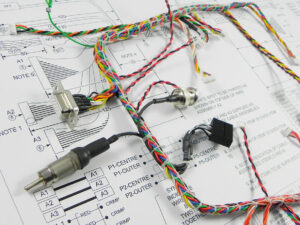

Custom cable assemblies are becoming more prevalent in industrial electronics as end users expect the same experience as they have with consumer devices. From an OEM’s standpoint, they offer an additional branding opportunity and can provide significant design and cost advantages over off-the-shelf products.

OEMs looking to outsource custom cable assemblies need to thoroughly evaluate suppliers to ensure they tick all the relevant boxes. A significant amount of effort is required to design, test, prove and produce custom assemblies so it is essential the partnership works on a long-term basis. It isn’t straightforward to move suppliers, so it is worth investing time at the start to prevent problems later on.

When assessing a prospective vendor, standard checks include longevity and financial stability. However, other checks include:

- What approvals do they have, such as ISO 9001 & 14001?

- Do they have other approvals demonstrating quality levels, such as the UL wiring harness traceability programme (an audit trail for components used in an assembly)?

What proportion of their cable assembly output is custom? - Do they have dedicated product experts?

- Do they have multiple manufacturing locations?

- Can they prototype quickly? An important factor for proving a design without delaying its launch.

- Do they have approvals needed to supply into specific markets such as medical, aerospace and defence?

A successful custom cable assembly project requires a close working relationship between the OEM and supplier. A good supplier will approach the original design with fresh eyes to establish opportunities for enhancements which could result in more repeatable production, lower finished product cost or lower overall applied cost, such as less time to install. They may also identify value-added opportunities including product branding and colour or additional features built into the assembly such as switches, fuses or PCB functionality. This holistic approach frequently results in a superior product at little or no additional cost.

The supplier will also look at cost-down opportunities for the assembly. These come in two main categories: component costs and manufacturing process. The BoM should be reviewed for lower cost equivalents, while the choice of production process can impact overall cost, lead times and tooling costs.

Requirements for cable assemblies supplied into specific vertical markets will often dictate the type of product required. For example, in hazardous environments issues include dust and moisture ingress, shock and vibration or even general wear and tear. Here over-moulding is the answer, with additional seals and grommets if waterproofing to a specific IP rating is required.

For the medical market, attention to detail and strict traceability and quality control are critical, as well as ISO13485 accreditation in some cases.

The aerospace and military markets require military specification cables and connectors. They also require a more stringent audit trail for the manufacturing process. Suppliers also need to be accredited to the worldwide AS9100 standard, which governs the entire manufacturing process, use of components and prevention of counterfeit parts.

In summary, manufacturing custom cable assemblies can be more complex than using standard product, but offers several key advantages to the OEM. Choosing the right supplier partner is crucial to the process.