As Rochester Electronics explains, when sourcing elusive components it’s important to understand the difference between AS6496 and AS6171/4 sources.

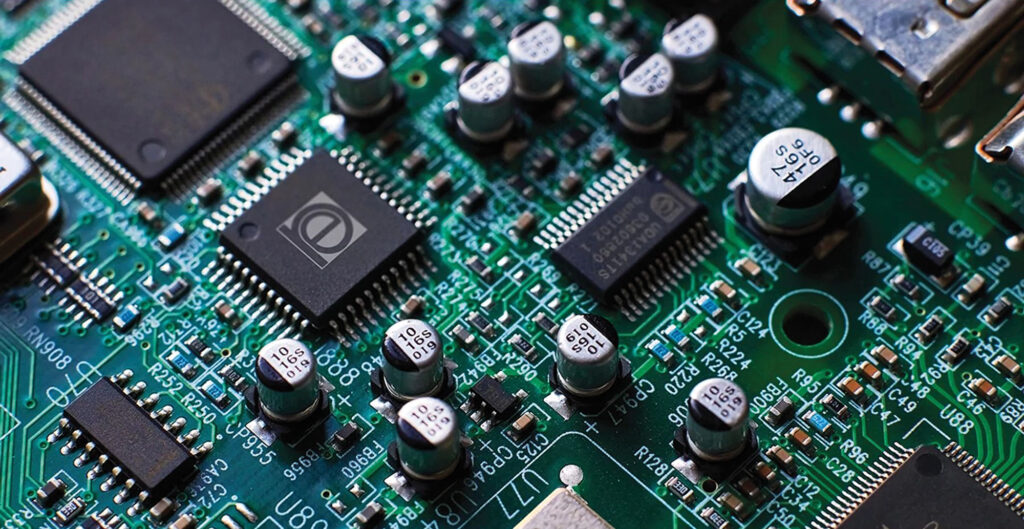

Recent supply issues have undermined normal delivery certainties. Covid-related manufacturing problems, shipping disruptions and even natural disasters have led to supply chain uncertainty and lengthening lead times. Component discontinuation notices have risen by 15 per cent over the same period, as third-party fab priorities changed and the industry refocuses fab investments to address a lower power, battery dominated landscape. Current semiconductor market shortages are widespread.

Customers are under pressure to guarantee supply and typically gray market or unauthorized sources are seen as the only solution. The counterfeit business sells through these gray market channels to infiltrate end customers. When time is tight and products are not available, the risk of end customers becoming victims of counterfeit products increases significantly. Tests and checks can be done to ensure products are genuine but they take time, are costly and in some cases, are not fully guaranteed.

The only way to ensure genuine product is to buy from an authorized source where devices have an absolutely guaranteed pedigree. Fully authorized distributors, like Rochester Electronics, identify themselves as compliant with the SAE Aerospace Standard, AS6496. Simply stated, they are authorized by the original component manufacturer (OCM) to provide traceable and guaranteed products with no quality or reliability testing required because the parts are sourced from the OCM.

Providers who are not, may market themselves as AS6171/4 compliant. This source, though better than no compliance at all, follows standardized inspections and test procedures with minimum training and certification requirements to detect suspicious or counterfeit components. This is an indication the parts are not sourced to the supplier from the OCM but have passed testing to minimize, not eliminate risk.

The supply chain shortage is presenting difficulties in different ways. Multisource devices such as power management and power discrete devices are being overwhelmed by demand. These devices may be available from multiple sources or have close equivalents among different suppliers. However, because of their widespread use, the sheer demand on supply has been persistent and has challenged suppliers to keep up.

Logic devices face a similar issue. They are used across a broad range of applications, producing constant demand. To resolve this challenge, customers are re-examining their performance requirements and opening date-code restrictions to improve sourcing options.

Microcontrollers and microprocessors are also being affected. MCUs and MPUs face design restrictions that limit alternative options and suppliers are faced with choosing the right product mix to manufacture. These devices are typically based on a particular CPU core, embedded memory and set of peripheral functions, resulting in specific package and pinout requirements, along with potential software and code impact. In general, the best option is within the same product families. Devices with larger memory, broader temperature range or higher performance may be available or an earlier revision that had previously been qualified is in stock and available as a drop-in solution. In more extreme cases, to keep a production line moving, customers may justify board re-spins to accommodate a different package.

In times of shortage and increased obsolescence, Rochester is positioned to provide support with its inventory of 100 per cent authorized components and range of semiconductor manufacturing services.

rocelec.com