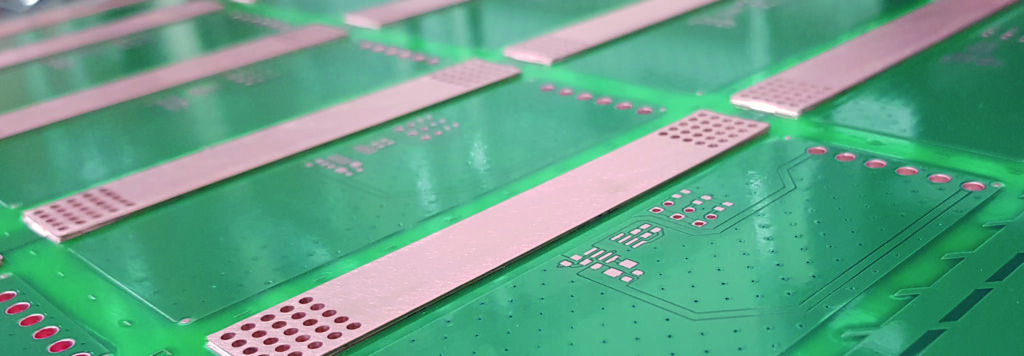

For every PCB that is sourced, manufactured and used, comes an end-of-life opportunity to recycle and reuse. TCL Elektronika explains

For every PCB that is sourced, manufactured and used, comes an end-of-life opportunity to recycle and reuse. TCL Elektronika explains

General military and civilian electronic systems are equipped with PCBs containing a variety of recyclable precious metals and important electronic components, some of which can be decomposed, recycled and reused, such as silver, gold, palladium and copper. The recovery rate of these precious metals can reach 99 per cent.

There are three main ways to recycle PCBs: heat, chemical and physical. Each has its pros and cons based on how the metal will be recycled.

Heat recovery: For this process, it is necessary to heat the PCB to a high temperature to recover the metals present on the board. Heat recovery will incinerate the FR4 but retain the copper. This process creates harmful gases such as lead and dioxin.

Chemical recovery: Here, an acid is used to recover metal from the PCB. The panel is immersed in acid, which destroys the FR4 and creates a large amount of wastewater that must be treated before it can be disposed.

Physical recovery: This process involves shredding, crushing, breaking and separating the metal from the non-metallic components. While this method has minimal environmental impact, there are still some downsides. There is a danger to workers because the process sends dust, metal and glass particles into the air which can lead to respiratory problems.

Recycling of waste printed circuit boards is expensive. Only the metal of the PCB has a reuse value, so the non-metal part needs to be separated which is an expensive process.

Take copper as an example. As one of the precious metals with a high recovery value, copper can be reused in a variety of applications. The first advantage of copper is its high conductivity. This means that it can easily transmit signals without losing power. It also means that manufacturers don’t have to use a lot of copper. In the most common configuration, one ounce of copper can be transformed into 35 microns covering a square foot of PCB substrate.

Examples of recycling resource-rich waste generated by the printed circuit board industry include:

- Metallic copper from the edge of printed circuits

- Tin from tin/lead slag in the hot air levelling process

- Copper oxide from sewage treatment sludge

- Copper from the basic etching solution

- Copper hydroxide from copper sulphate solution in the plated through hole process

- Copper recovery from the rack stripping process

- Copper from the tin/lead stripping solution used up in the solder stripping process.

As a specialist PCB manufacturer, TCL Elektronika pays attention to manufacturing technology and PCB design capabilities, while also working to recycle scrap printed circuit boards, hoping to reduce the impact of this type of electronic waste on the environment and ecology.

www.tclelektronika.com