Note Windsor’s logistics manager, Brendon Jones, explains the tactics used to support customers through the turbulence of extended lead times and cost increases

Note Windsor’s logistics manager, Brendon Jones, explains the tactics used to support customers through the turbulence of extended lead times and cost increases

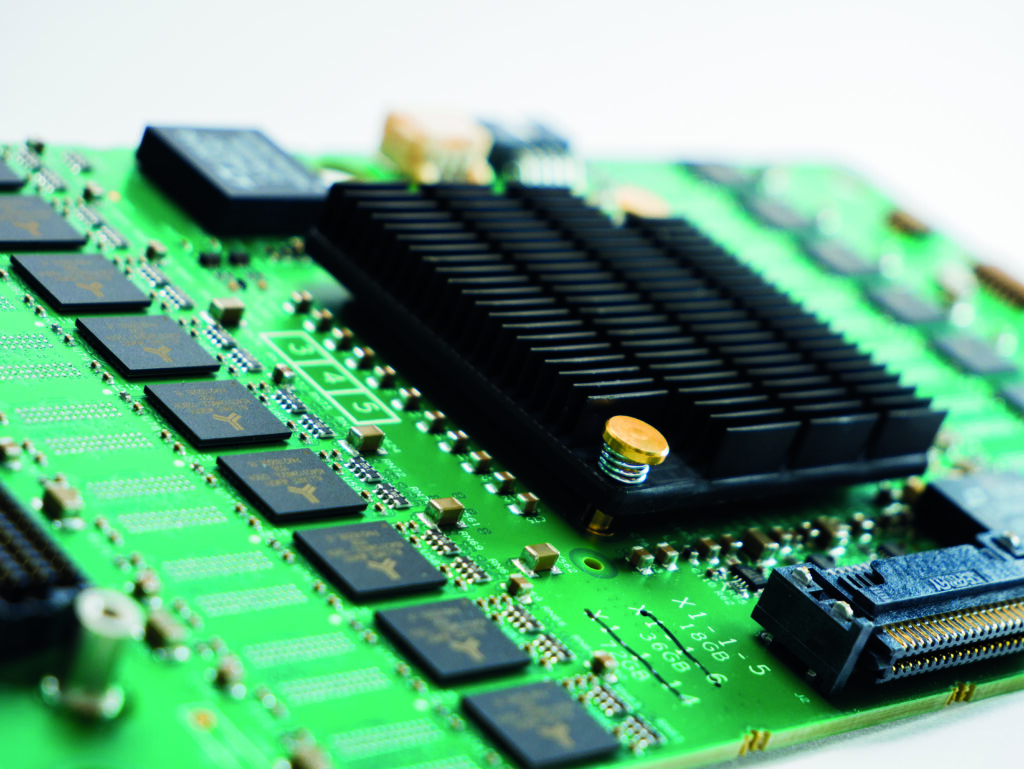

The global pandemic had a considerable impact on the component market back in 2021. This continued and, in some cases, worsened for some during 2022. The franchised distribution network has been challenged by lead-times that component manufacturers are experiencing and as such, the CEM and its customers have needed to seek alternative sources or designs.

As a CEM providing a procurement and assembly service to its customers, it is our task to remove supply chain stress and resolve issues to ensure the best supply to meet customers’ demands.

We still experience supplier decommits without any notice, extending lead times when placing new orders and price increases. Price increases can be at point of dispatch from the supplier. This has influenced our business and our customers’ businesses.

We expect material shortages to ease during the latter half of 2023, although we do not expect all prices to return to pre pandemic levels.

Being part of a larger group has given Note UK access to approved and audited independent supply partners. Early in the supply chain disruption in 2020, it became obvious to customers that engaging with independent suppliers to gain the broadest sweep of the component market, proved counterproductive, particularly in respect of pricing. We often saw the component market respond by increasing prices exponentially in relation to the number of enquiries received. We have the experience to engage with the Group’s partnered independents to keep the level of false demand down and ensure a good supply chain for customers’ needs.

During the increasing scarcity and component costs, many customers took the opportunity to investigate alternative parts or redesign elements of their PCBAs to secure component supply. There are challenges to both these options using up valuable resource and time. This obviously impacts lead time for the finished product. Note UK relied on its ability to secure alternatives, coupled with its rework expertise to modify circuitry or component footprints, to allow fitting of alternative parts, easing the pain for customers.

On top of these challenges, we also experienced added freight and logistics costs. Partly due to the pandemic, there were increased shipping costs and extended lead times. Even as these costs and lead-times have improved, the need to deliver final products to customers often means engaging with express delivery services.

Through all of this, true value is regular communication between suppliers, logistics, customers and CEM to negotiate supply chain issues together, plus collectively managing cost, lead-time process or product designs so everyone gets the most out of a challenging market.

This has been a tough journey. To our customers, we thank you for your patience and for collaborating with us whilst we work through this challenging market.