CTX Thermal Solutions’ MD, Wilfried Schmitz, introduces the benefits of extruded and cold extruded aluminium application specific SMD heat sinks

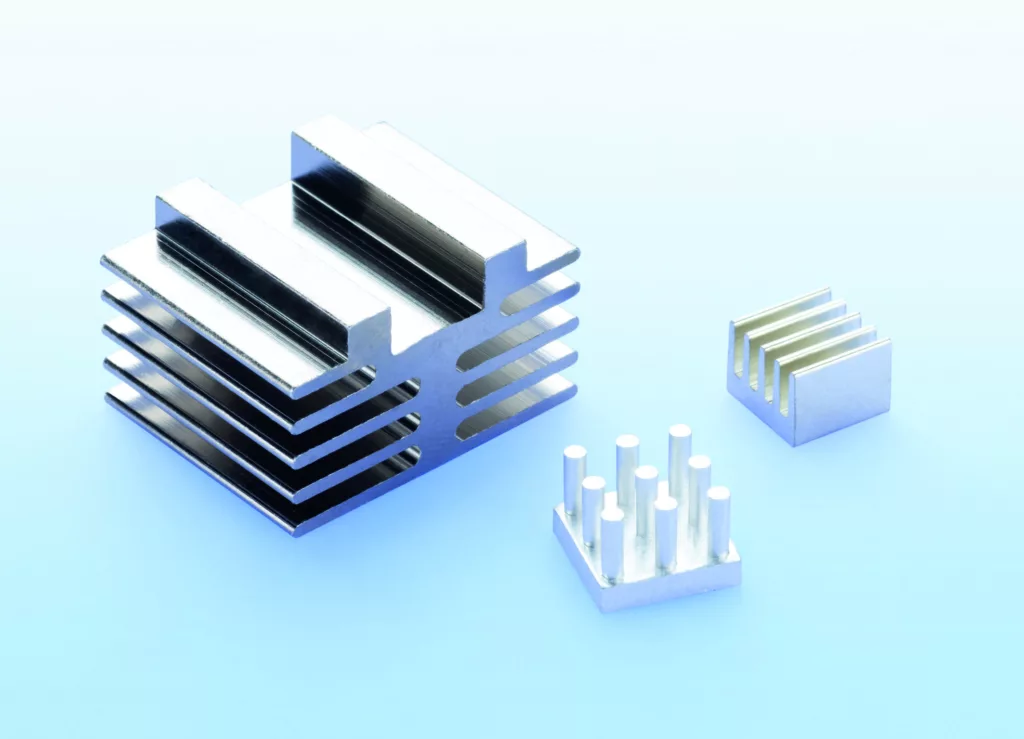

CTX has expanded its line of SMD heat sinks. In addition to standard SMD heat sinks for all common D-PAK modules, the supplier now offers extruded and cold extruded aluminium SMD heat sinks designed and produced for specific thermal requirements.

CTX Thermal Solutions’ MD, Wilfried Schmitz, said: “In the past two years, the demand for custom SMD heat sinks has increased considerably. CTX meets this demand with application specific SMD heat sinks manufactured from continuous cast aluminium alloys or high-grade aluminium. Like standard SMD heat sinks, the extruded or cold extruded heat sinks are available in bulk or as tape-and-reel material.”

Three options are offered for bonding the semiconductor and heat sink. A manual bond is achieved by applying a thermally conductive adhesive to the semiconductor contact surface and then placing the SMD heat sink on the electronic element to be cooled. For automated processing, SMD heat sinks are provided with a double-sided adhesive thermally conductive foil for bonding to the semiconductor. Alternatively, extruded and cold extruded SMD heat sinks can be pre-tinned to enable manual or automated soldering to the PCB to create a secure bond to the semiconductor element.

Compared to standard SMD heat sinks—stamped and formed from copper then tinned—extruded or cold extruded aluminium SMD heat sinks feature important advantages. Both processes allow implementation of highly individual heat sink geometries with large surfaces, making them as efficient as copper heat sinks. Application-specific SMD heat sinks have the added advantage of much lower material and process expenses.

www.ctx.eu