Machine control panels are susceptible to electromagnetic interference so SCHURTER is offering purchasing professionals ten tips to sidestep this potential problem

Machine control panels are susceptible to electromagnetic interference so SCHURTER is offering purchasing professionals ten tips to sidestep this potential problem

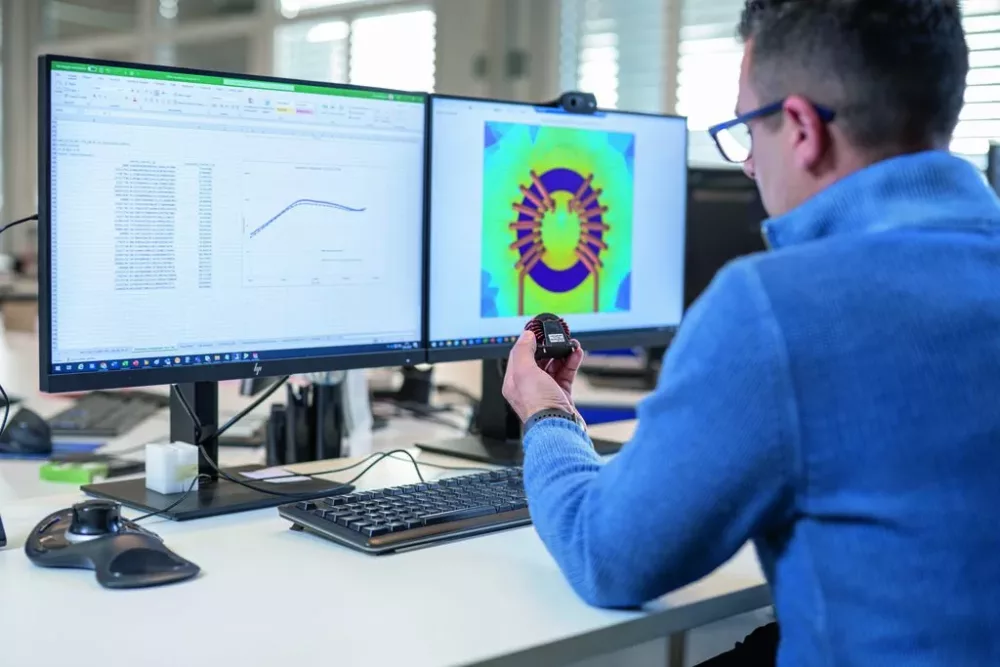

When developing applications to comply with the electromagnetic compatibility directive (EMC), consider these ten essential factors:

1. Compliance awareness: Begin by understanding relevant EMC standards/regulations, especially if products are CE marked and destined for the European market. For specialised applications like medical equipment, specific EMC requirements apply.

2. Early EMC integration: Initial concept and design stages should consider EMC. Early attention prevents later design alterations. Identifying EMC-sensitive components or processes before the engineering phase helps avoid costly revisions.

3. Environmental assessment: Understand the operating environment. Evaluate external radiation sources and potential for interference. Additionally, examine internal electronics as they can emit electromagnetic radiation.

4. Prevention is key: While control panels can be modified to enhance EMC, it’s often easier to minimise emissions from the surrounding environment and bolster immunity beforehand. Consider measures such as adding filters to interference sources or using shielding.

5. Component selection: Opt for materials and components known for high immunity to electromagnetic interference. Insulated cables and suppression components can significantly contribute to achieving desired EMC levels.

6. Software solutions: Software can mitigate radiation-induced interference by shifting working frequency to a less congested band, a technique known as frequency hopping. This approach ensures uninterrupted operation despite interference.

7. Pre-compliance testing: Conducting EMC tests during development provides clarity about the application’s performance. It’s more efficient and cost-effective to make adjustments early.

8. Technology choices: While PCAP touchscreens are popular, alternatives like membrane switches, push buttons or resistive touchscreens may suit some applications due to lower sensitivity to electromagnetic radiation or the possibility of complete shielding.

9. Housing design: Optimise the control panel’s housing by integrating dense metal enclosures acting as Faraday cages. Seal openings for cables with radiation-resistant adaptations to maximise immunity.

10. Co-engineering: Collaboration with EMC specialists is essential during development. As a custom control panel manufacturer, SCHURTER offers specialised EMC expertise to the design, production and integration of control panels across various sectors.