Harting introduces a process designed to replace flexible printed circuits, letting original equipment manufacturers benefit from simplified installation and cost savings

Flexible printed circuits are established components in many products thanks to their adaptability. However, assembling and fixing these circuits can be a complex process. To simplify installation and deliver cost savings, Harting has developed a new component carrier solution based on 3D Mechatronic Integrated Devices (MID) technology.

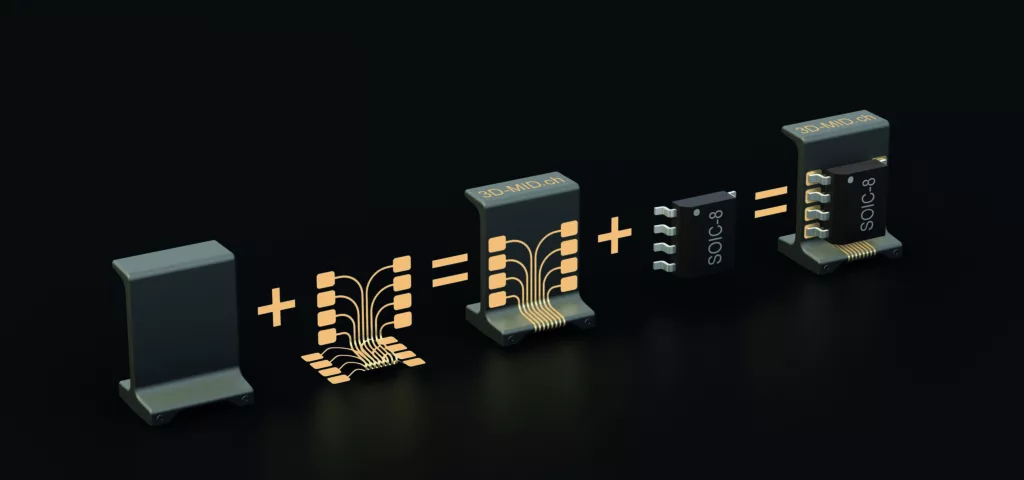

This means electronic components can be fitted directly onto the carrier, replacing flexible circuit boards. The carrier provides a connection between the printed circuit board and components such as LEDs, ICs, photodiodes and sensors.

Carriers are constructed using Laser Direct Structuring (LDS), which applies conductor paths directly onto plastic parts. The base body is injection moulded and material additives are activated by laser, letting the material accommodate electrical conductor paths. It can then be assembled using standard surface mount processes or soldered in a reflow oven.

Resulting assemblies can be flexible, complex geometric designs. Products such as smart phones, hearing aids and smart watches can become smaller and more powerful. LDS also allows production of 3D-MID assemblies, meaning components can be fitted directly onto a three-dimensional base body without circuit boards or connecting cables.

Component carrier technology suits various applications. As a stable, reliable process it has become established in quality-critical sectors such as medical technology and production of safety-relevant automotive components.

Another recent application is security covers for payment terminals. The covers protect internal components from unauthorised mechanical

and electronic access, increasing transaction security and preventing theft.