Antistat explains how its focus on listening to customers is helping the company develop products and services that meet business, technical and environmental needs

As an ISO:9001 manufacturer to the electronics sector, Antistat has been helping its customers meet electrostatic discharge challenges for over 35-years. The company’s focus has and always will be its customers, spending time listening to customers’ needs and evolving its processes and supply chain to ensure timely delivery.

Post Covid, guaranteed supply is a key factor in customers’ decision making, recently compounded by geopolitical, financial and environmental factors. With the desire to reduce reliance on China and the resultant investment in semiconductor manufacture nearer home, Antistat has been working hard expanding its distribution network within Europe and North America to provide an efficient streamlined supply chain without compromising on quality.

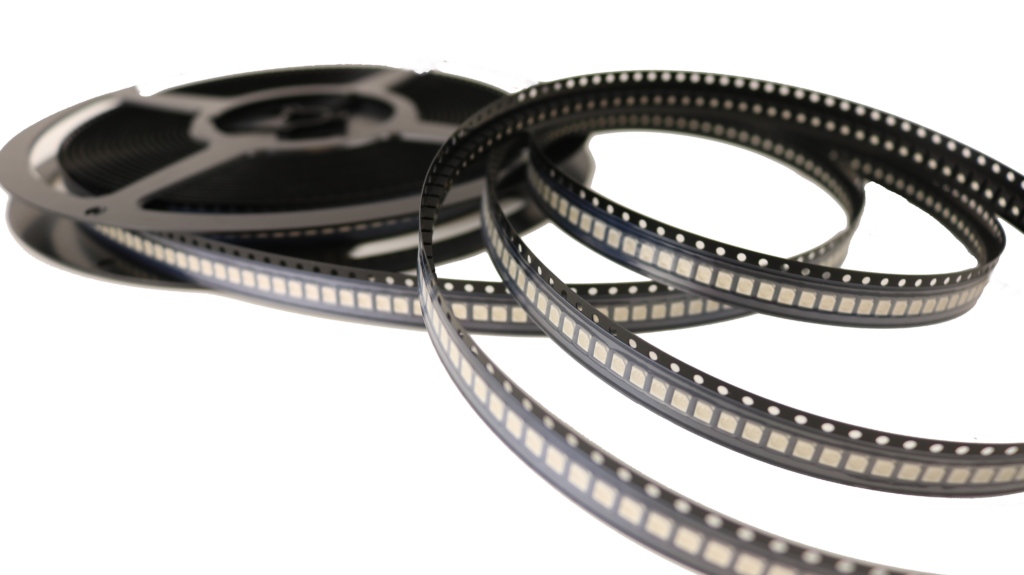

In addition, 2024 sees the launch of new carrier tapes. Developed in accordance with the EIA, JIS and EIAJ standards, the range offers widths from 8 to 72mm, with over 600 sets of open tools. Custom designs and sizing will be available with fast turn arounds.

Supply chain sustainability is a core strategy for 2024. Antistat is committed to promoting a positive impact socially, environmentally and economically throughout its global operation. The company strives to reduce carbon miles through stock consolidation and in-plant stock programs. Freight time and carbon miles are reduced thanks to a global distribution network, while innovative replenishment modules remove the need for external packaging during transit which reduces waste.

Regarding products, Antistat is developing a range of 100 per cent recycled ESD packaging with the potential to replace 15 million single use pink antistatic bags per annum.