Pektron explains how a significant investment in integrating solder paste inspection is improving end product quality and reliability.

The Surface Mount Technology Association states 74 per cent of PCB manufacturing process defects are solder paste related. This is why integrating solder paste inspection (SPI) machines into an SMT line is essential to ensure the quality and reliability of electronic components.

Consequently, Pektron has made a significant investment in adding the latest 3D SPI machines to all its lines. This gives control, facilitates optimal solder paste use, improves quality and provides cost savings.

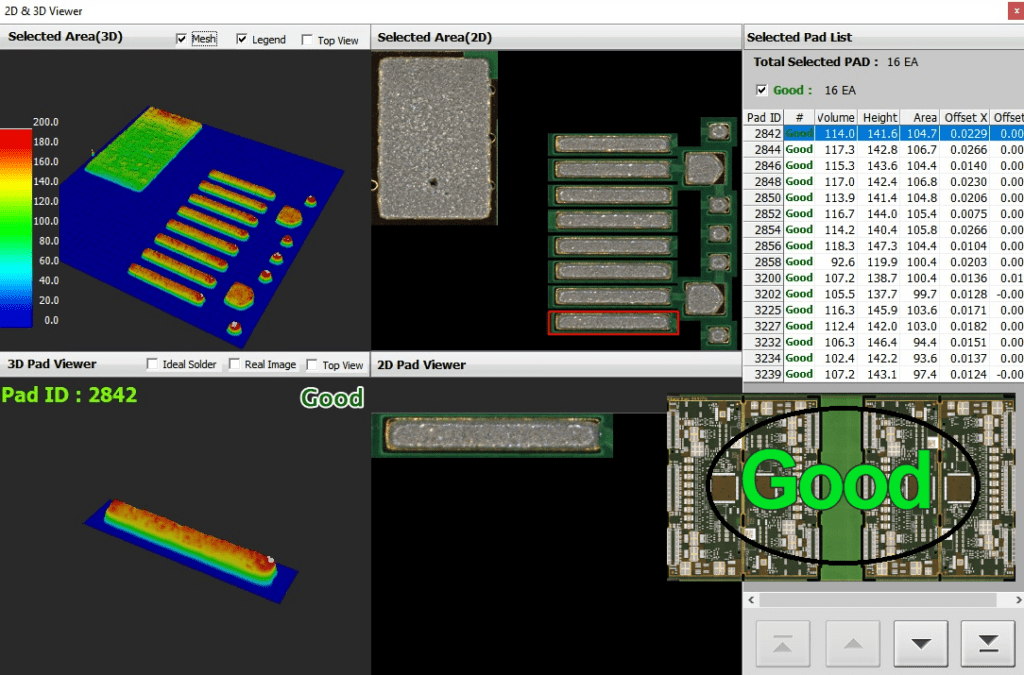

A key feature of SPI is the ability to accurately measure solder paste deposits in 3D. This allows reliable detection of defects such as insufficient or excessive paste volume, bridging and misalignment. Importantly, this wealth of information is used to continually improve and actively prevent issues.

Using the SPI data, the solder paste print process is controlled in a real-time closed-loop system. The SPI machines provide ‘live’ performance feedback enabling monitoring and prompt rectification of issues.

SPI machines contribute to increased product reliability with precise measurement ensuring solder paste is accurately applied, to prevent short circuits or poor connectivity that can lead to product failures. This is crucial in industries where electronic devices are subjected to harsh conditions or stringent performance requirements, such as agriculture, off-highway, automotive or safety.

Pektron’s proactive inspection approach significantly improves product reliability and customer satisfaction. The integration of SPI machines into its SMT lines lets the company stay ahead in competitive markets where this level of manufacturing precision and quality control is essential for meeting the demands of modern electronics.