In2tec’s sustainable electronics ambassador, Emma Armstrong, explains the company’s solution for the removal and reuse of electronic components from PCBAs

According to The Circularity Gap Report, the current global economy is just 7.2 per cent circular (dropping from 9.1 per cent in 2018), meaning that for the most part, materials are mined, created into products, sold and then disposed of. This wasteful way of life has sadly been the norm for decades.

Circularity in the electronics industry was historically deemed an impossibility due to multiple challenges, including the complex construction of conventional PCBAs and the limited repair, recycling and reusability options. The process to separate components from a substrate is costly, while the stress caused to de-soldered components leads to their questionable viability.

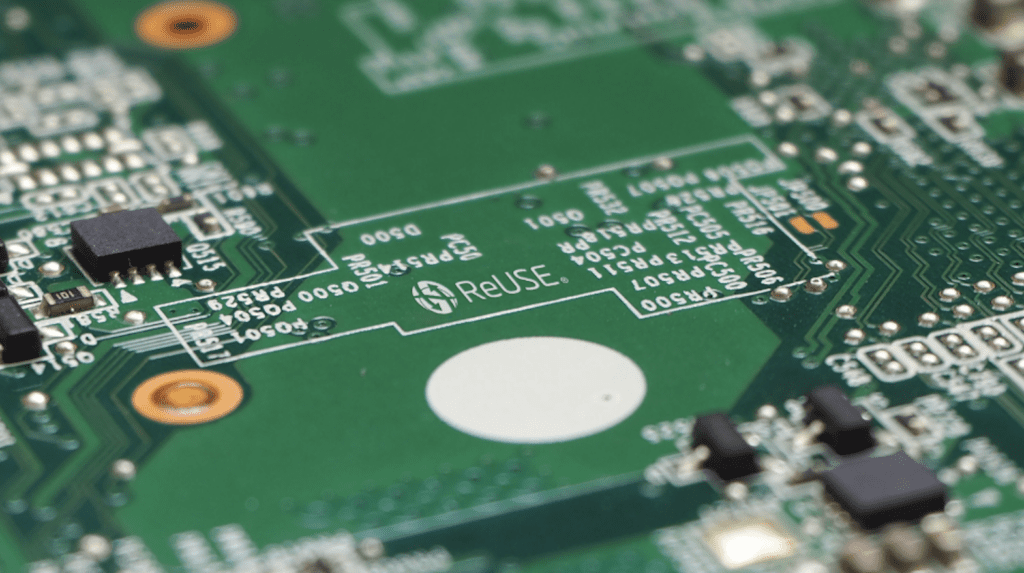

These issues and associated costs have consistently been at the heart of the global e-waste problem and why the outcome to-date is to bury or burn it. In2tec’s sustainable electronics solution, ReUSE and ReCYCLE, is a closed- loop process allowing manufacturers to remove components from existing electronics at the end of their useful life and reuse them.

ReUSE is a suite of patented inks, adhesives, materials and process and utilises proprietary design techniques to manufacture PCBAs. ReCYCLE is the ultra-low energy process for unzipping PCBAs back to the original bill-of-materials (BoM). The components are returned without causing stress or damage, allowing for their reuse in other products or for resale in the growing second-life market.

In2tec’s sustainable electronics ambassador, Emma Armstrong, said: “Our technology allows manufacturers to easily repair and extend the life of products or reuse them in manufacture. We’re bringing full circularity to the electronics industry and minimising the use of raw materials and minerals that are rapidly running out.”

Linear economies cause devastating pollution to our water, soil and air while raising the earth’s temperature to unstable levels. More than 90 per cent of materials are either lost or remain unavailable for reuse. The Global Electronics Council reported that within the 57Mt of e-waste generated in 2021, over $60bn of valuable components were wasted.

Emma continued: “The electronics industry needed a solution to minimise waste by reusing existing components that in most cases have been used for barely a quarter

of their viable lifespan.”

In2tec’s solution means that e-waste becomes a value chain, not a cost chain. Manufacturers reduce the costs spent on components and WEEE charges and create additional revenue streams through the resale of valuable components and materials by OEMs and recyclers.

A number of large OEMs are engaged with In2tec to better understand the technology and the benefits it will have for introducing a circular economy to their manufacturing processes. The closed-loop processbrings financial gain to OEMs and, with over 70 percent of a PCB’s CO coming 2 from first-life components, it also dramatically cuts their CO2 emissions in manufacture and disassembly.

Emma concluded: “The current linear economy isn’t just unsustainable; we can’t let it continue. Global resources are running out and for the benefit of future generations we need to reuse what we already mined. The electronics industry must address its impact on the planets resources, and having a solution that provides value means we’re seeing OEMs take an interest in ReUSE and ReCYCLE.”