Princeps demonstrates the power of XRF spectroscopy, an effective non-destructive analytical technique used to determine the elemental composition of materials

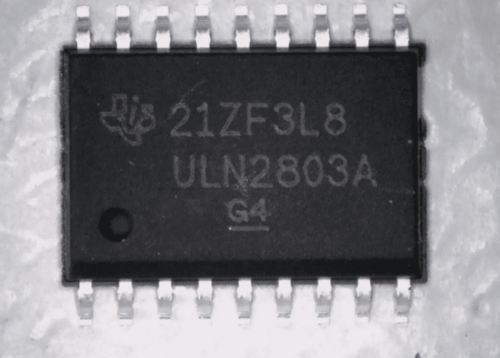

Purchased from a European broker, the part in Figure 1 is a replacement part for a Darlington Transistor Array—discontinued

by the manufacturer (without lifetime buy option) in September 2022—with no form-fit- function (F3) replacement offered or available.

The G4 marking denotes the lead plating. These markings are defined in the J-STD-609 IPC/JEDEC standard. G4 indicates a precious metal finish, specifically with no tin (Sn). In this case, the parts should have nickel- palladium-gold (Ni Pd Au) plating, over a copper- iron (Cu Fe) lead-frame.

XRF spectroscopy was utilised on this batch, as part of the inward quality inspection process, to confirm the plating’s material composition. The resulting spectra (Figure 2) shows a large amount of tin (in red) and no indication of gold or palladium.

Many test houses use XRF to verify whether a part is RoHS-compliant or not. The results obtained with these parts did show them as RoHS-compliant. However, the red flag isthe unexpected plating. The parts were rejected as suspected counterfeit, reported via the ERAI and removed from the supply chain.