In this article, NCAB explains how together with its suppliers and customers the organisation wants to create a more sustainable industry with growth and profitability for all.

Sustainability is a central part of NCAB Group’s way of thinking and acting. When working with customers, the company highlights the various aspects of PCBs (design, production and delivery) which can have a positive impact on sustainability. NCAB’s strategy defines its long- term goals and focus areas. With clear priorities, the strategy guides the company in the right direction to gain sustainable business growth and help achieve positive changes in the industry.

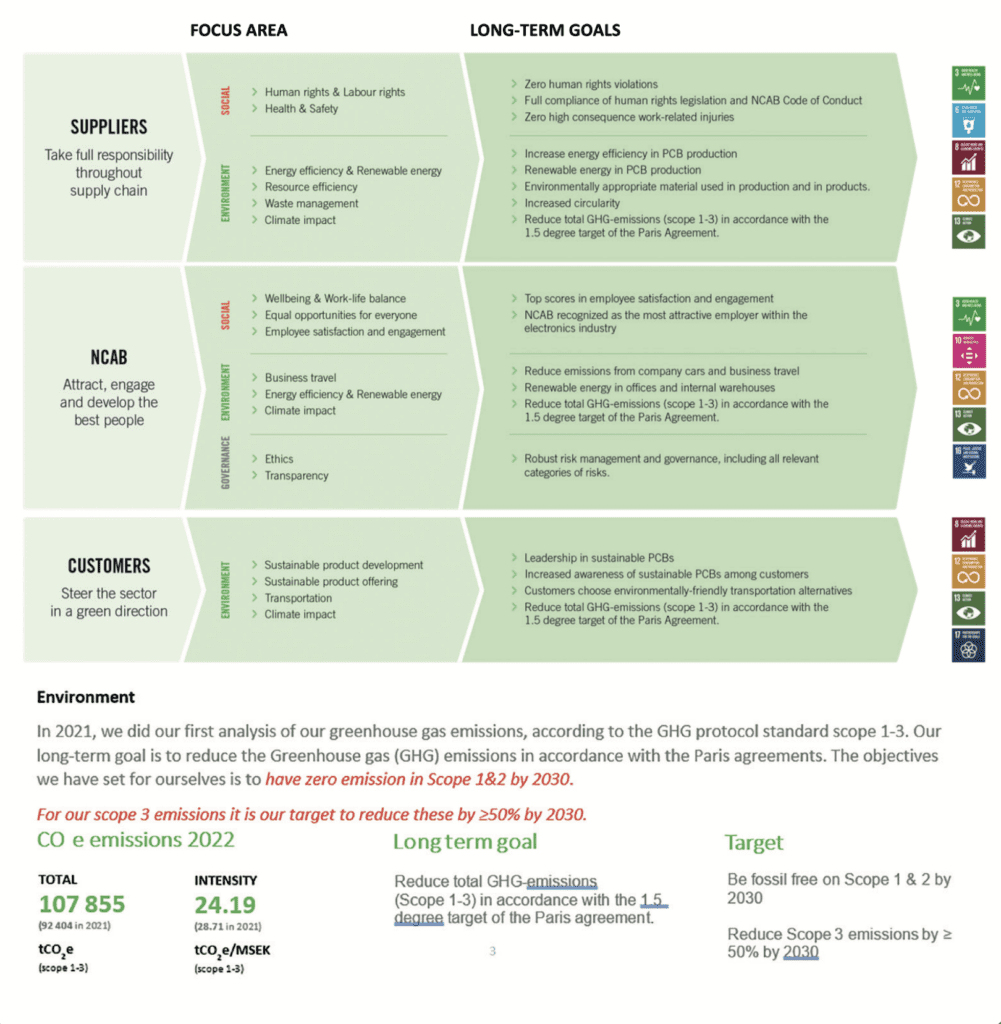

NCAB implemented its first sustainability strategy in 2014, with a latest update in February 2022. The strategy specifies long-term goals and focus areas, which set concrete actions. Through sustainability work, together with stakeholders, the company is working towards achieving the Sustainable Development Goals (SDGs) and is contributing mainly to eight out of the 17 goals.

In an era where technology is ever present, making sustainable choices in PCB manufacturing is not just an option, it’s an imperative for a brighter, more responsible future.

Sustainability initiatives have been well received by NCAB’s customers, resulting in market share gains, especially in the EV and renewables sector. In addition, new clients—who have a corporate policy of purchasing from sustainable sources—have been attracted. NCAB is Ecovadis Gold rated, fostering closer collaboration with customers.

EV charging market

One industry NCAB serves is electric vehicle charging (EVC), where EVs are revolutionising and shaping modes of transportation. The company has experts who have been supporting the current trends and requirements

for EVC PCB design.

PCB considerations when designing for EVC units:

• Miniaturisation

• Material properties

• Thermal Management

• Trace width and thickness

• Power copper (Cu) weights

• Solder mask thickness

Quality is controlled throughout the PCB process. The initial PCB design significantly affects the PCB’s total cost and reliability. All local NCAB offices include dedicated specialists who work with customers to understand their requirements and those of the product. The design support teams can advise on value-engineering initiatives. They are aimed at helping achieve the best possible design or redesign for cost- effective PCB production from prototypes through to volume production.

Tools for design support

By optimising resource usage, minimising waste and decreasing pollution, PCB manufacturers can contribute to a healthier planet. Moreover, adopting sustainable practices can lead to cost savings, increased efficiency and improved brand reputation, making it an economically viable choice.

NCAB has derived various design tools for engineers, including the Cost Driver tool to support the design phase which gives engineers a ‘sustainability impact meter’. Circuit board cost drivers are divided into two categories: hard and soft costs. Hard cost drivers cover aspects relating to the physical PCB itself. Examples are copper weights and build complexity. In these cases, impacts on cost and sustainability are more tangible.

Soft cost drivers are elements that unless considered can lead to delays in engineering, lost time and mis-specified demands that only serve to either drive cost upwards or fail to identify what is needed to achieve the desired quality or long-term reliability— this is not sustainable PCB production in our eyes. In the Sustainability Impact meter it is possible to see the effects for each cost driver.

One example of a PCB cost driver is size. This is one of the simplest drivers to understand. Just as with real estate, the larger it is, the more it costs. Aside from simply the use of more material, other considerations are:

• Should a defect occur in a smaller circuit, the remainder of the panel can still be acceptable for production

• When a defect occurs in a larger circuit a larger portion of raw material is discarded

• Environmental impact of material demand. Less material = lower environmental impact

Environment

In 2021, NCAB did its first analysis of greenhouse gas emissions, according to the GHG protocol standard Scope One to Three. The company’s long-term goal is to reduce greenhouse gas (GHG) emissions in accordance with the Paris agreements. The objective NCAB has set for itself is to have zero emission in Scope One and Two by 2030. For Scope Three emissions, the target is to reduce these by 50 per cent by 2030.

NCAB’s activities do not stop with stakeholders and factories. The company plans to continuously infiltrate customers with knowledge about its journey to both support and influence bestpractice where possible. This will continue with seminars, webinars, open days and sustainability reports to aid the re-shoring of the supply chain for a more positive impact on the environment.