This month’s counterfeit investigation from Princeps shines a spotlight on an important and effective new detection method that is becoming more and more useful.

Fourier-transform infrared spectroscopy (FT-IR) is a well-established non- destructive technique for characterising materials by analysing their interaction with infrared light. Princeps’ uses FT-IR to analyse polymers used to encapsulate electronic components, either via comparison with a known good device or by contrasting a device’s top and bottom surfaces. It’s a good alternative to destructive, often subjective solvent resurfacing tests, and is diagnostic in nature.

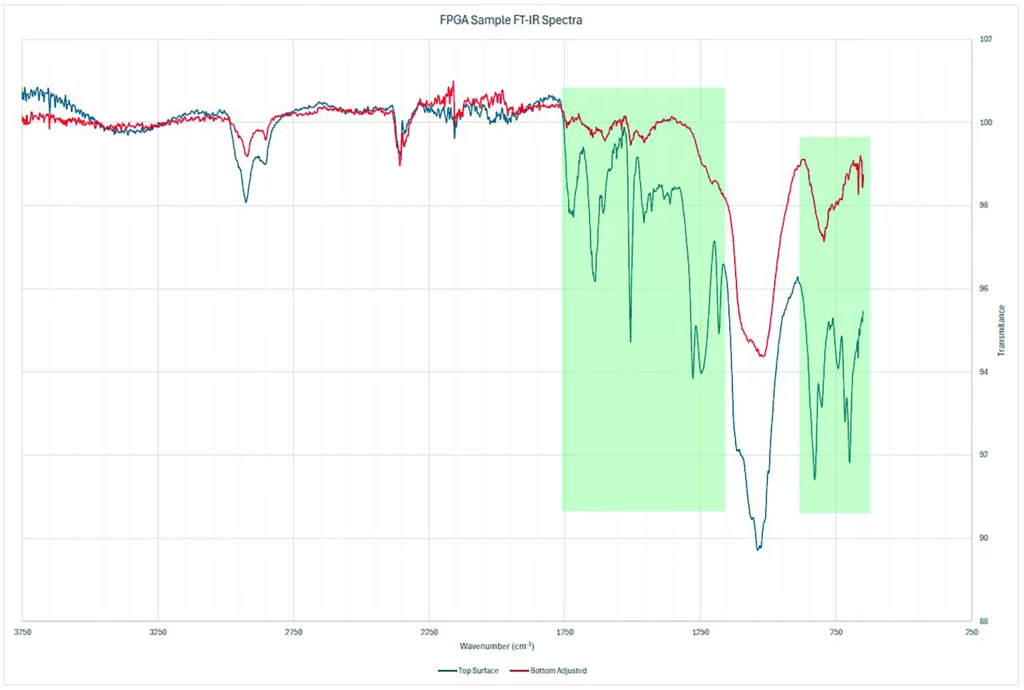

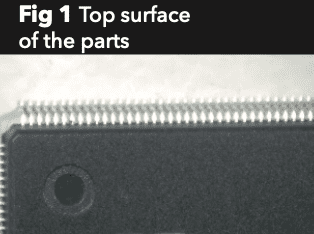

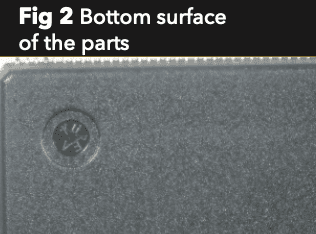

The part tested in this example is an FPGA in a QFP package. At first sight, the product appears as expected, with clean pin release marks and pin 1 markers (Fig 1 and Fig 2). However, when the device was analysed using FT-IR, some marked differences between the results for the top and bottom surfaces were observed.

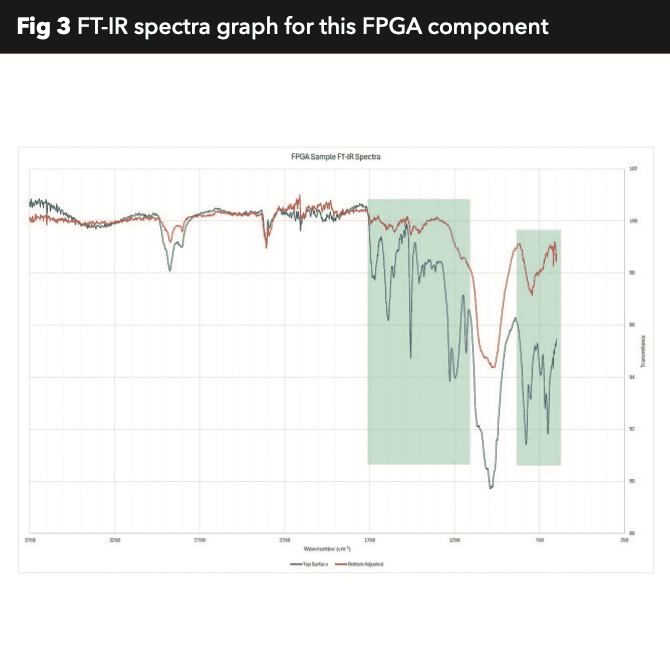

The graph in Fig 3 shows the resultant spectra: a genuine plastic encapsulated part should have matching top and bottom surfaces, resulting in practically identical spectra for both surfaces. In this case, the top surface (Fig 1) is the blue trace and the bottom surface (Fig 2) is the red.

The highlighted green areas indicate the sections that we are concerned with in this example. The blue trace shows something ‘extra’ in the top surface, which is not seen on the bottom (possibly an epoxy coating), suggesting the part has been resurfaced at some point, probably to disguise older or slower parts and pass them off as newer or faster components.

As usual, the parts were rejected as suspected counterfeit, reported via the ERAI and removed from the supply chain.