Whether OEMs are at the design stage of a new product or looking to revamp an existing product, Lincoln Binns’ ECS stand will showcase helpful design and customisation services

Whether OEMs are at the design stage of a new product or looking to revamp an existing product, Lincoln Binns’ ECS stand will showcase helpful design and customisation services

Lincoln Binns manufactures and stocks five different ranges of enclosure solutions that can all be customised with cut-outs, inserts, sub panels, artwork and colour schemes to match OEMs’ branding and expectations. The Lincoln Binns’ team will walk visitors through the process, drawing on years of engineering and design experience.

Services offered include CNC punching, CNC milling, laser cutting, folding, full colour digital printing and laser etching, anodising and powder coating.

The E-Case range is a rugged industrial aluminium enclosure with a range of mounting accessories including: DIN rail, VESA mount and several surface mounting options. The enclosures are designed to house three standard board sizes: 55, 100 and 160mm wide.

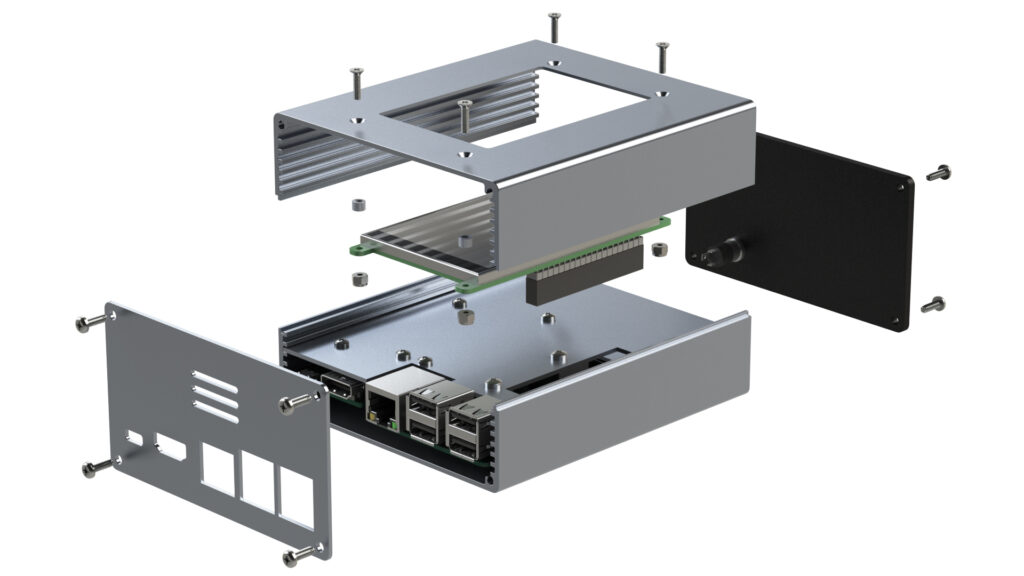

The Combi-Case range is a two-part aluminium enclosure featuring a more aesthetically pleasing design. The Combi-Case has been designed to house a 100mm wide board with a removable lid.

U-Case and UnioBox ranges are six-piece electronics case kits that comprise two side extrusions 1U, 11/2U, 2U and 3U in height. The enclosure can be manufactured to different widths and lengths. The U-Case range utilises the same accessories as the E-Case.

Lincoln Binns’ 19in rack range of enclosures and panels feature 1U, 2U and 3U blanking and extruded panels, plus 1U, 2U and 3U full enclosures. Stocked in fixed depths, they can be manufactured to any depth up to 500mm.

For OEMs looking for something unique, Lincoln Binns can design and manufacture extrusions or bent metal boxes.